HVAC TECH

Building Management System

Today, it is quite difficult to manually control a building's equipment, utilities, power, lighting and other energy resources without a reliable and effective control system that ensures the comfort and safety of the people who live and work in the building. Moreover, it is difficult to maintain the equipment and utilities and optimize the resources used. For this reason, building management systems are used to control all systems and energy efficiently and effectively.

What is Building Management System?

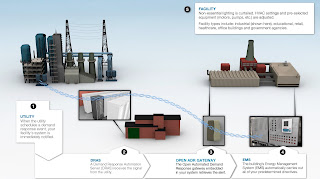

A Building Management System is a system for controlling, managing and monitoring devices such as: air conditioning system, lighting system, heating system, ventilation, power supply, door locks, etc.

A Building Management System is a computer-based system that is installed in a building. Building Management System hardware and software were originally developed in the 1960s. Over the years, the IT infrastructure for Building Management Systems has grown organically and many improvements have been made in control, communication, protocols, networking, etc. In today's fast-changing world, Building Management Systems contain mostly incompatible devices and infrastructure.

Nowadays, all commercial buildings are controlled by a Building Management System (BMS) to reduce energy losses and improve control of the systems.

Below are the components and parameter which controlled by Building Management System:-

System for managing heat consumption

System for controlling water supply and pumping system

Temperature Control valve of Air conditioning systems

On-off control for air conditioning system

Controlling Building lightning system

It control smoke detectors and fire hydrants alarm system

Fire alarm system, fire and other emergency warnings system

Building Doors interlocks system

BMS also control the volume control valve of air conditioning system

Advantages of Building Management System:-

The main advantage of BMS is becoming energy efficient by controlling and minimizing energy uses and the waste of energy

Improves the quality of our system and make easier to control

Provide security to our business or Building

Improve the indoor environment safety and quality of our HVAC system

Reduces the our equipment operating cost

Reduces the resources of natural environments

HVAC TECH

https://hvactech.in

Comments

Post a Comment